Our company use the most modern systems of 3d scanning. Through the scanning process we are able to digitalize an object and accurately reproduce it....

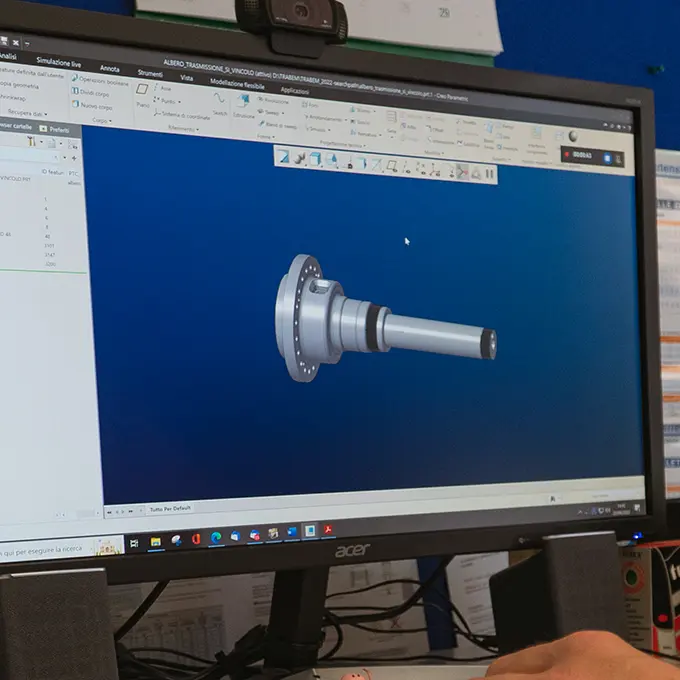

Discover more 3D scan and reverse engineeringIn our technical office the scanned models are re-elaborated digitally and they are the starting point on which the mould mechanics is developed....

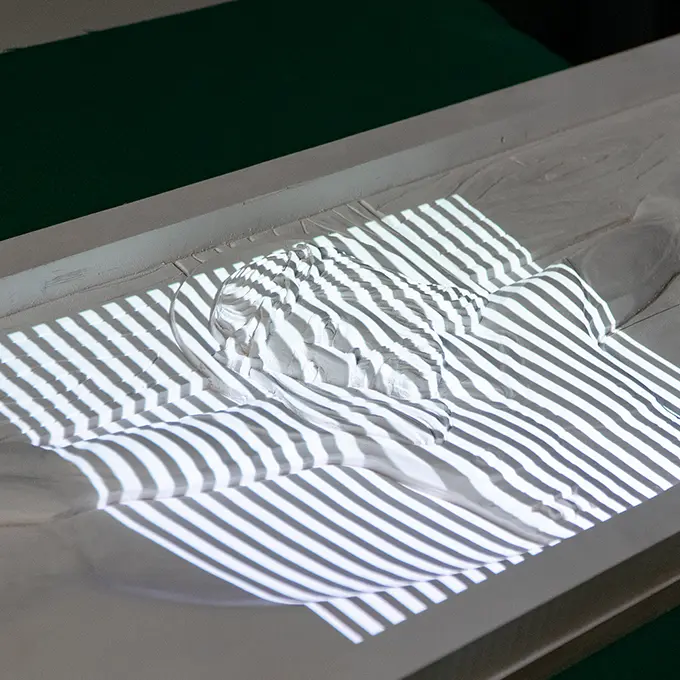

Discover more Digital prototypingTo validate the mould functioning, our company supply a test embossing service. ...

Discover more Embossing tests and samplingOur company provides a service of revision and recondition of used machines. We mostly work on roller embossing machine and hot embossing presses of d...

Discover more Machine reconditioningThe embossing technique is particularly suggested for latest generation materials processing, such as recycled materials....

Discover more Upcycling